Goals

The original skateboard frame had some issues. It was easy to have the end of the board hit the ground while riding up hills. The squarish design would drag a corner while making even moderate turns. There were also issues with accessing the internal electronics and controllers, making it difficult to quickly update the software. The skateboard itself was quite heavy, weighing about 38 pounds. That made it difficult to lug around, especially with the lack of a good place to grab it.

On the other hand, there were several aspects of Skate One that worked well. I wanted to keep the good stuff, and upgrade everything else. If you're interested in the details of the first skateboard, read up on it here.

Design

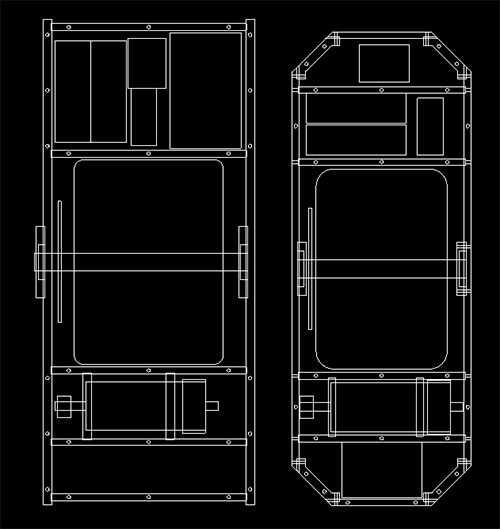

I fired up the old 2D CAD program and started laying things out. The various design tweaks included:

- I moved the axle down 1" farther from the top of the deck.

- The deck is now only 2" deep instead of 2.5"

- This allows for 1.5" more clearance between the bottom of the deck and the ground, giving 5 degrees of additional rotation before the frame hits the ground.

- The corners have been rounded, allowing for better clearance while turning.

- The sprocket on the axle was moved closer to the wheel, again improving clearence while turning.

- I tightened up the spacing on all components, and used 3/8" aluminum bar instead of 1/2" thick bar nearly everywhere.

- This resulted in 2" narrower design. If it was narrower you'd have issues with toe and heel overhang for large feet.

- Overall length remained about the same. You'd need smaller components to shrink the length any further.

Building

I had most of the aluminum laying around that I needed, so I jumped in and rough cut the frame members. I started out with 11 pounds and 8.8 ounces of aluminum. I also chose a knobby wheel this time around,

as the slick wheel on Skate One tended to lose traction on grass.

I was reminded how much I enjoy machining once I got into it. This design was similar to the typical Team Cosmos frame, so things fell into place quickly. I did pick up a new indexable boring bar,

which made making the motor mount much easier. I also pocketed the frame members, which I had never gotten around to on Skate One.

By far the trickiest part of the machining was building the corner supports. These started out as 1" thick aluminum bar. A lot of setup time and specialized jigs were involved to get the

compound angles right. They also had tabs that dovetailed into the other frame members.

After about 6 months of casual machining, I had the basic frame. Pretty damn sexy, if I do say so myself. Final weight came to 6 pounds, 14 ounces, including bolts. So I'd removed about 5 pounds of

aluminum during the build. Doing some quick math, it looked like this skateboard would weigh about 25 pounds, roughly 10 pounds less than the original.

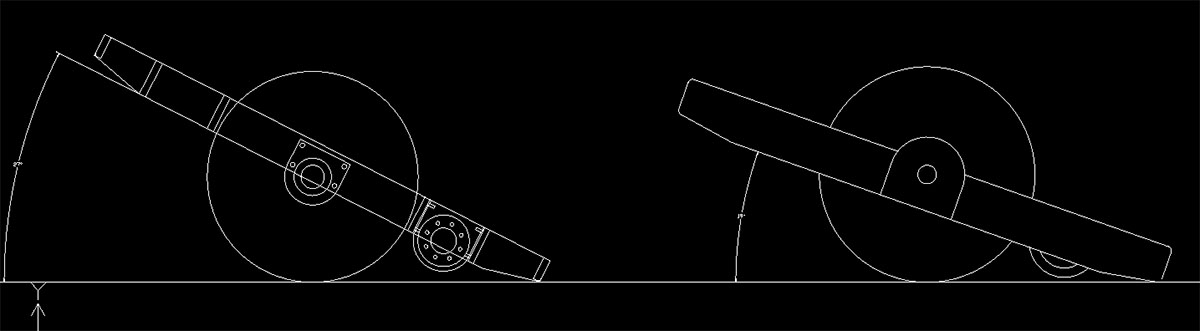

Here's a comparison between the old frame and the new. The increased clearance meant a much more severe angle at rest. This might make getting on the board a bit challenging.

Now the tedious part of the machining started. That last 20% takes 80% of the time, as the saying goes. There were countless small tasks to complete. Mounting brackets, top and bottom plates,

enclosures for electronics, etc. These tasks really dragged on. Luckily I was able to work on the electronics and software in parallel, giving me a break from sitting in front of the mill.